Rtd: READY TO DELIVER

Ready to innovate. Ready to collaborate. Ready to fulfill. For the most trusted, safest and highest quality ready-to-drink beverages in the industry, Portland Bottling Company is ready to deliver.

As the Pacific Northwest’s leading beverage co-packer for nearly a century, Portland Bottling Company and its team across multiple facilities provides flexibility and responsiveness, with a wide geographical reach, as well as the scale to handle your needs.

Explore Our Capabilities

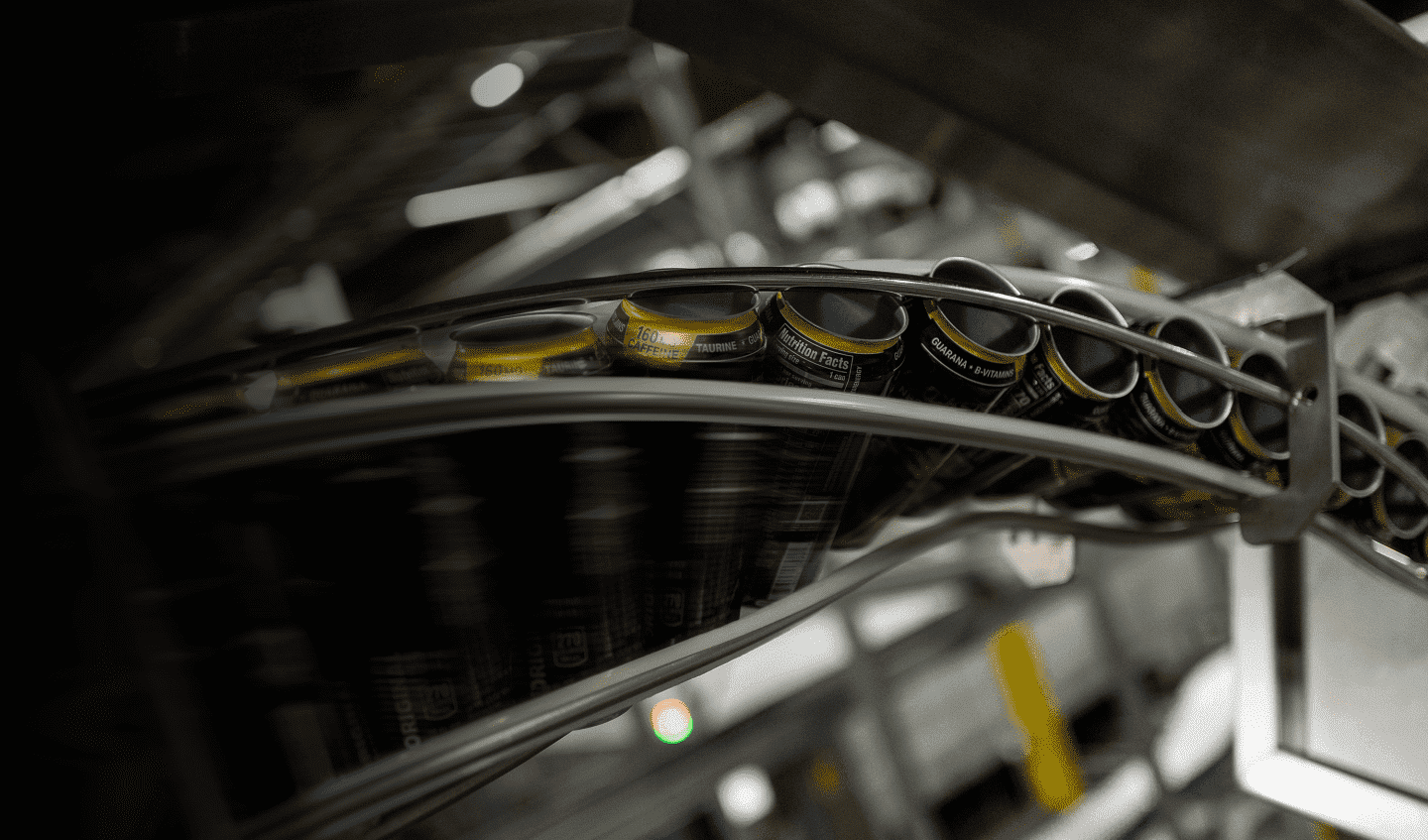

We can a wide variety of ready-to-drink (RTD) beverage products in aluminum cans, ranging from juice-based products, energy and functional drinks to sparkling waters in a wide variety of can sizes. With the ability to can up to 1,450 cans per minute, we are the partner of choice for leading and independent beverage companies and brands across the Pacific Northwest and nationwide.

Cartons. Loose packs. Variety packs. Whatever your needs, our state-of-the-art facilities can meet your requirements with standard and customized options to ensure your product is delivered exactly as you want it, on time and to the highest quality standards.

Our advanced, fully integrated system enables us to seamlessly fill and then carton 4 packs, 8 packs, 12 packs, 24 packs and more. Our automated technologies rapidly carton and palletize with paramount quality and efficiency.

We offer on-site warehousing, as well as off-site warehousing solutions to meet any and all of your needs. Our building is controlled access with 24/7 security, as well as advanced video surveillance technologies to protect your most valuable assets.

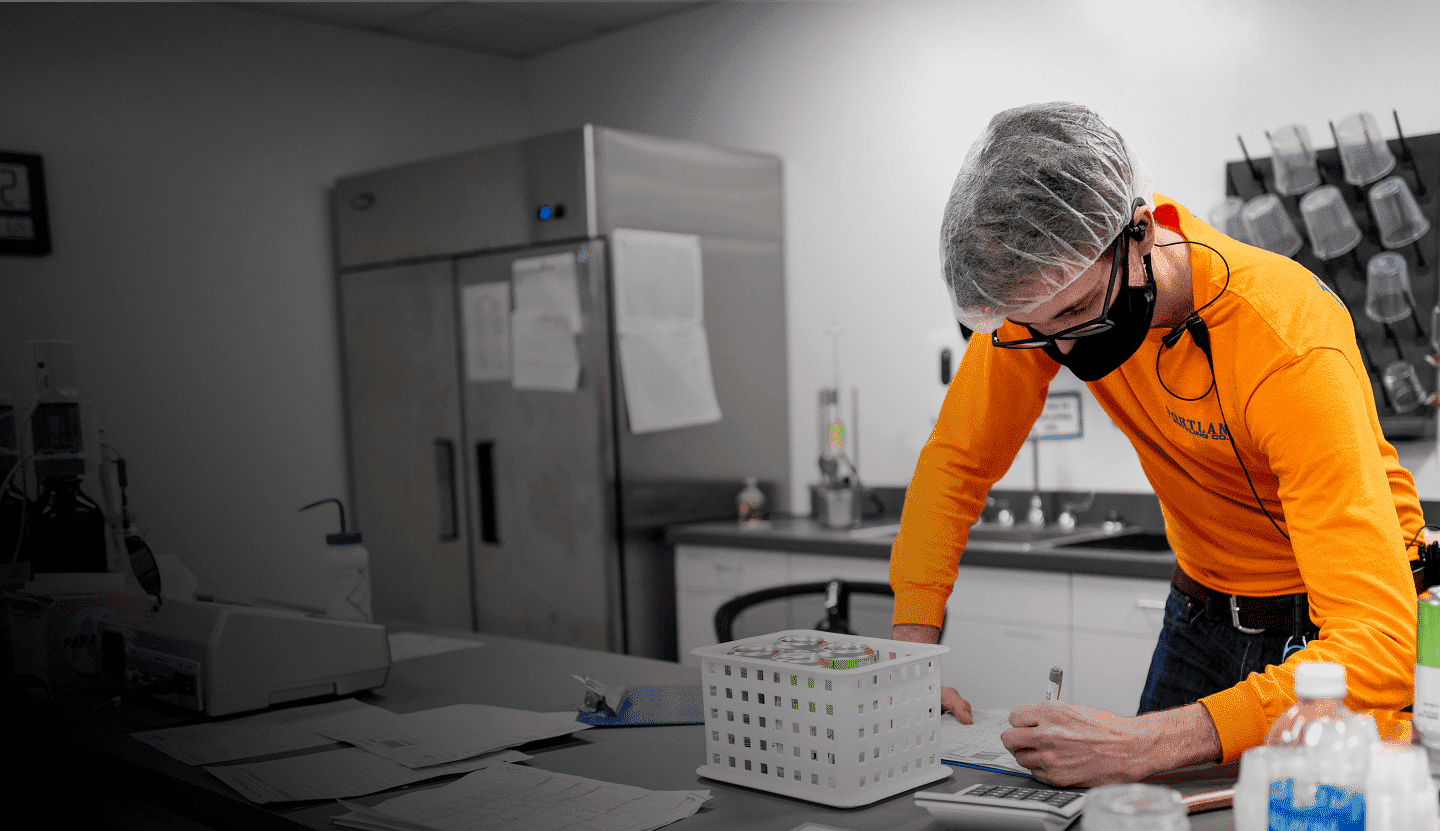

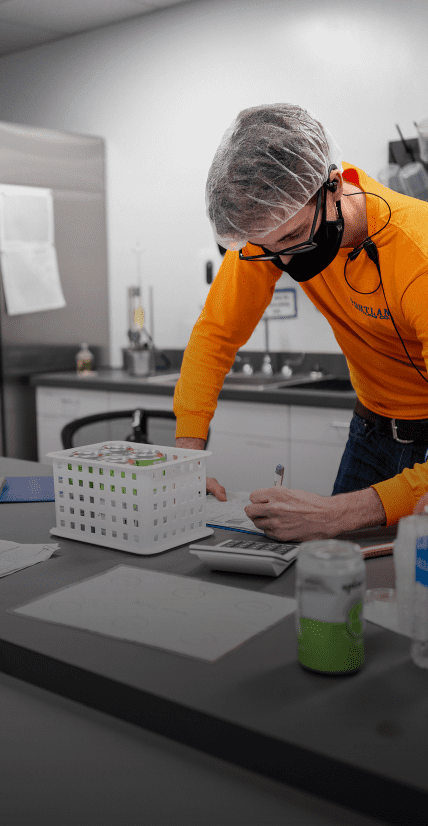

Portland Bottling Company performs to the highest quality assurance standards, including on-site QA labs and automated, state-of-the-art inline monitoring throughout the production process. We are FSSC 22000 certified, strictly adhere to HACCP regulations and frequently audit our facilities via a third-party auditor to rigorously maintain compliance.

Portland Bottling Company’s multiple production, storage and repacking locations (over 600,000 square feet) include a new state-of-the-art canning and co-packing facility, with the most advanced technologies and robust capabilities of any packer in the Pacific Northwest – and rivaling those of any co-packer anywhere in the United States. We offer 24/7, end-to-end solutions for next-level quality, reliability, efficiency and yield. Most importantly, our people don’t sit back; we proactively communicate and enable solutions through every stage of the production process.

Be part of a winning team that’s delivering innovative solutions and high-quality beverages for some of the nations’ leading brands. Work with dedicated and collaborative people who thrive in a fast-paced environment. Our Clackamas operations include a brand-new facility with the latest, most advanced equipment.

Learn from experts with decades of experience. Take advantage of our generous package of compensation, benefits, services, and support to help you succeed. And take your career to the next level with skills and opportunities you won’t get anywhere else. If you think you have what it takes to be part of a company that strives to create a working environment that stimulates team spirit, passion, engagement and achievement, please apply today.

See Open Positions

“Working at Portland Bottling Company is a chance to be a part of building something from the ground up. There is an emphasis on building a positive culture. It’s a great place to start or continue your career, and we have a fantastic future and growth plans.”

“The team here is full of knowledge and willing to take the time to teach you something new. Most production employers just throw the operators in and expect them to land on their feet. Here they want the team to succeed and will find the proper tools to help each individual.”

“Two things separate Portland Bottling and any other company I have worked for. First, everyone knows everyone, and it’s very family oriented in ways. Second, the plant is a real team. Everyone makes a difference in their own way, and we all work towards the same goal, rather than separate ones in different departments. Portland Bottling Company is a team you just can’t refuse.”

“I would recommend anyone join Portland Bottling company for the atmosphere of working with great people with a lot of valuable knowledge in manufacturing energy drinks, and because it could be a great experience. I know it is for me.”

If you’re looking for a partner to exceed your expectations and deliver added value at every turn, we’re ready to deliver for you. Let us continuously work with you to improve the yield, quality, safety and affordability of your products.

Contact Us